Our philosophy

PanelTech Systems is driven by the belief that the construction industry deserves innovative, sustainable alternatives to traditional building methods.

Our story

PanelTech Systems was founded in 2024 with the vision of providing the construction industry a viable alternative to the traditional stick build method.

Drawing inspiration from the offsite prefabricated construction methods that have been used in the Northern hemisphere since post World War Two, it has been extremely prevalent in countries like Sweden, Germany and America all for various reasons. We saw this as an opportunity to bring a relatively unknown technology to the Australian market that has long been lagging behind the rest of the world when it comes to offsite prefabricated construction methods.

PanelTech Systems is the only Australian company with the ability to manufacturer the SIP (Structural Insulated Panel) product and deliver it to site in the form of a full wall section already precut for windows, doors and services we achieve this via our SIPS (Structural Insulated Panel System).

Our process

The SIPs process is a streamlined approach to constructing energy-efficient homes using structural insulated panels (SIPs).

Our process involves multiple stages, beginning with the SIPS design of the house, moving on to panel manufacturing, testing and assembly, transportation to the construction site, and concluding with final completion. The process is designed to ensure precision and efficiency at every step, from creating the individual panels to assembling the walls, roof, and parapet roofs. Through each stage, the panels are carefully assembled and tested, ensuring a robust and sustainable structure. Below, we outline the detailed stages and steps that bring the SIPs process to life.

STAGE 1: Design

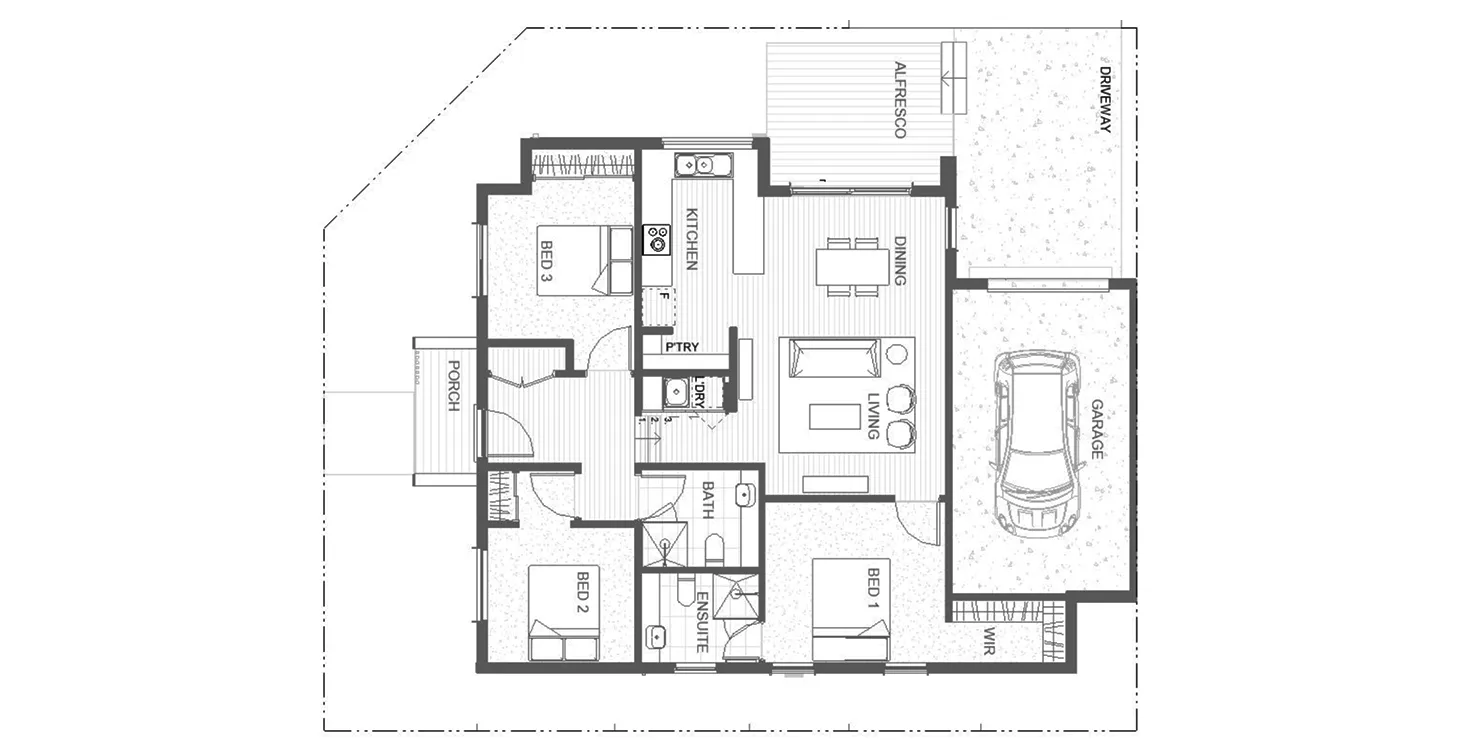

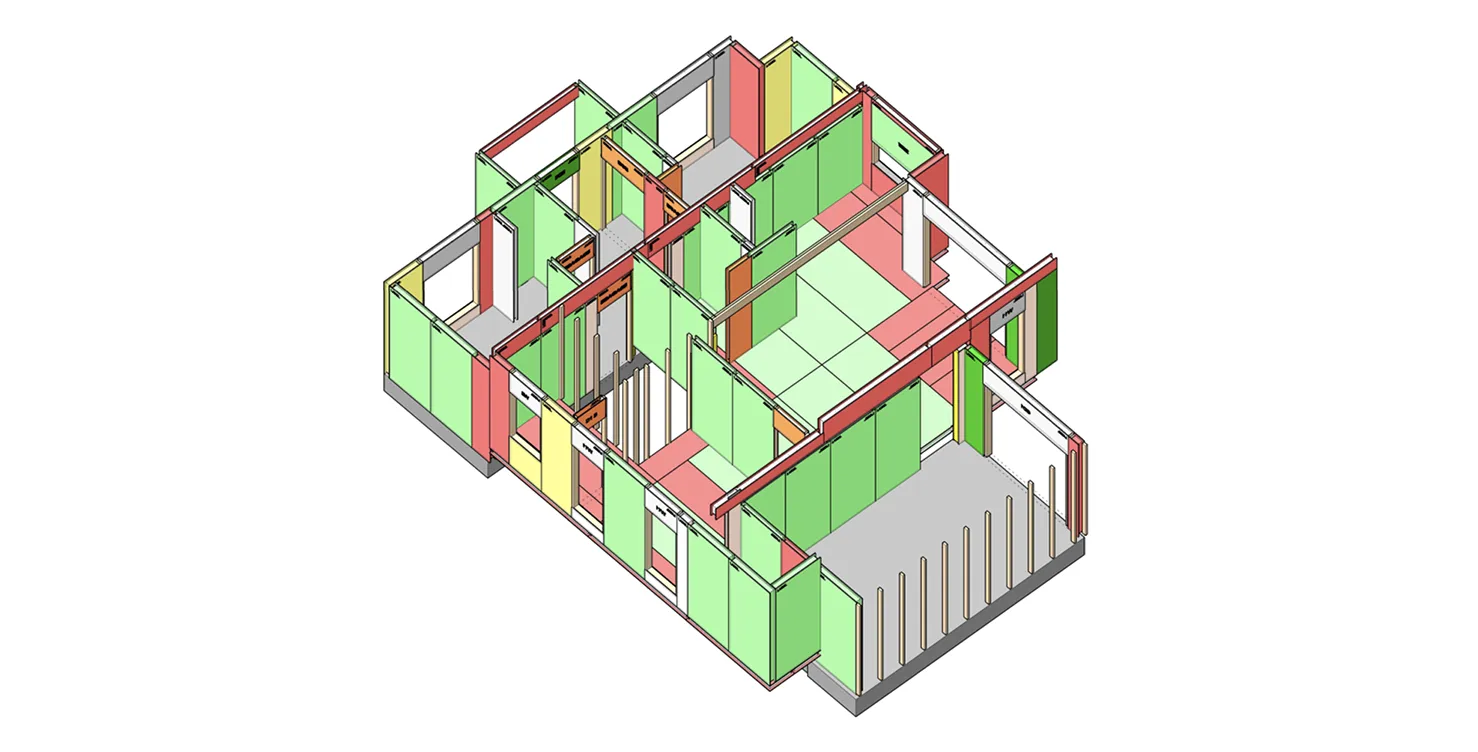

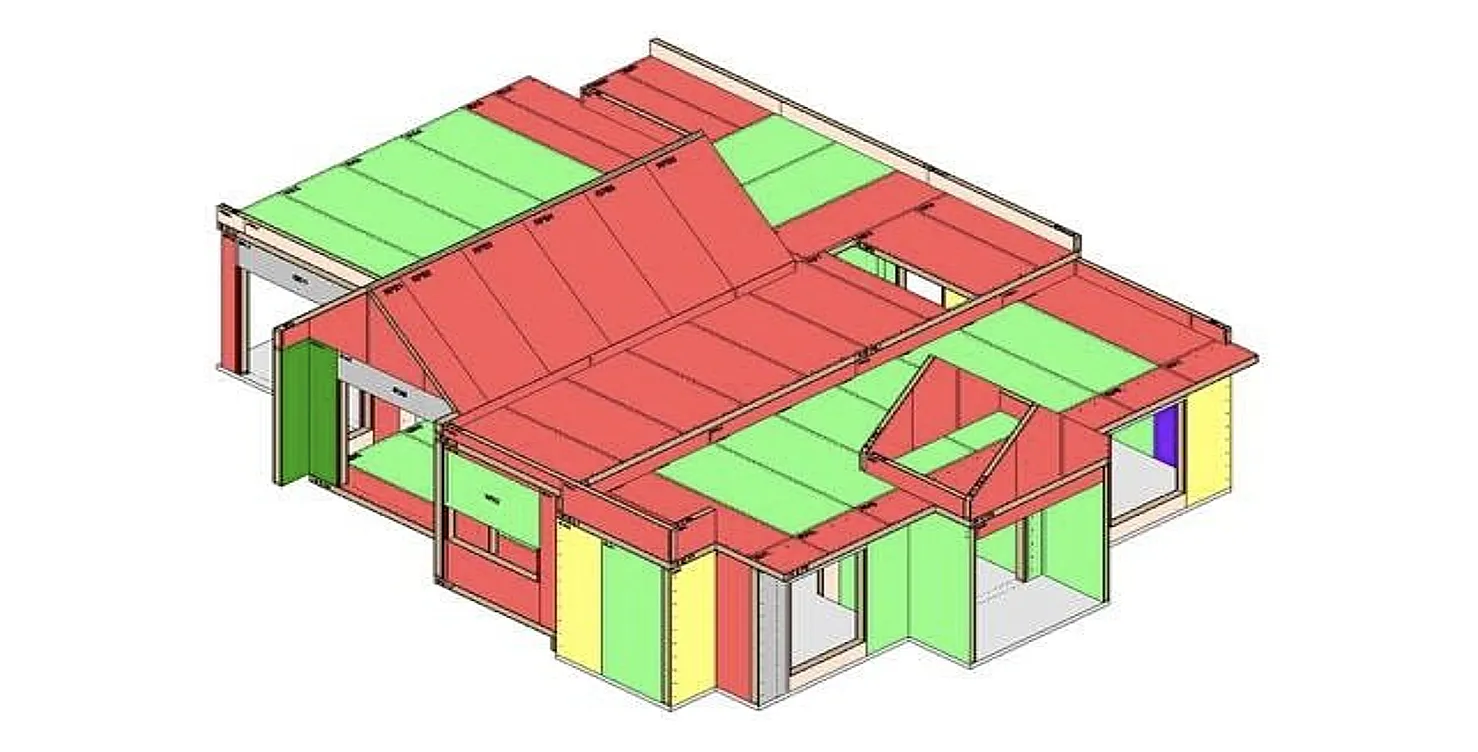

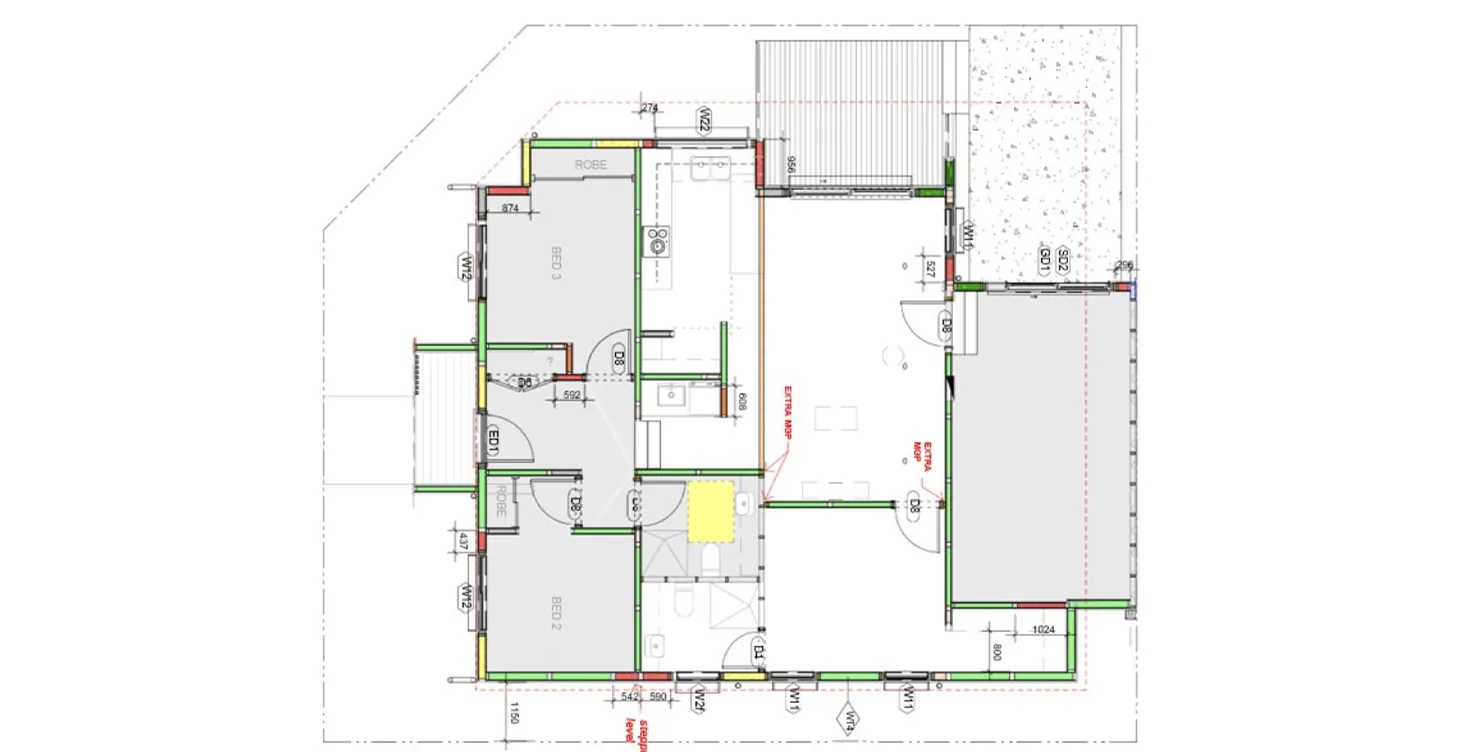

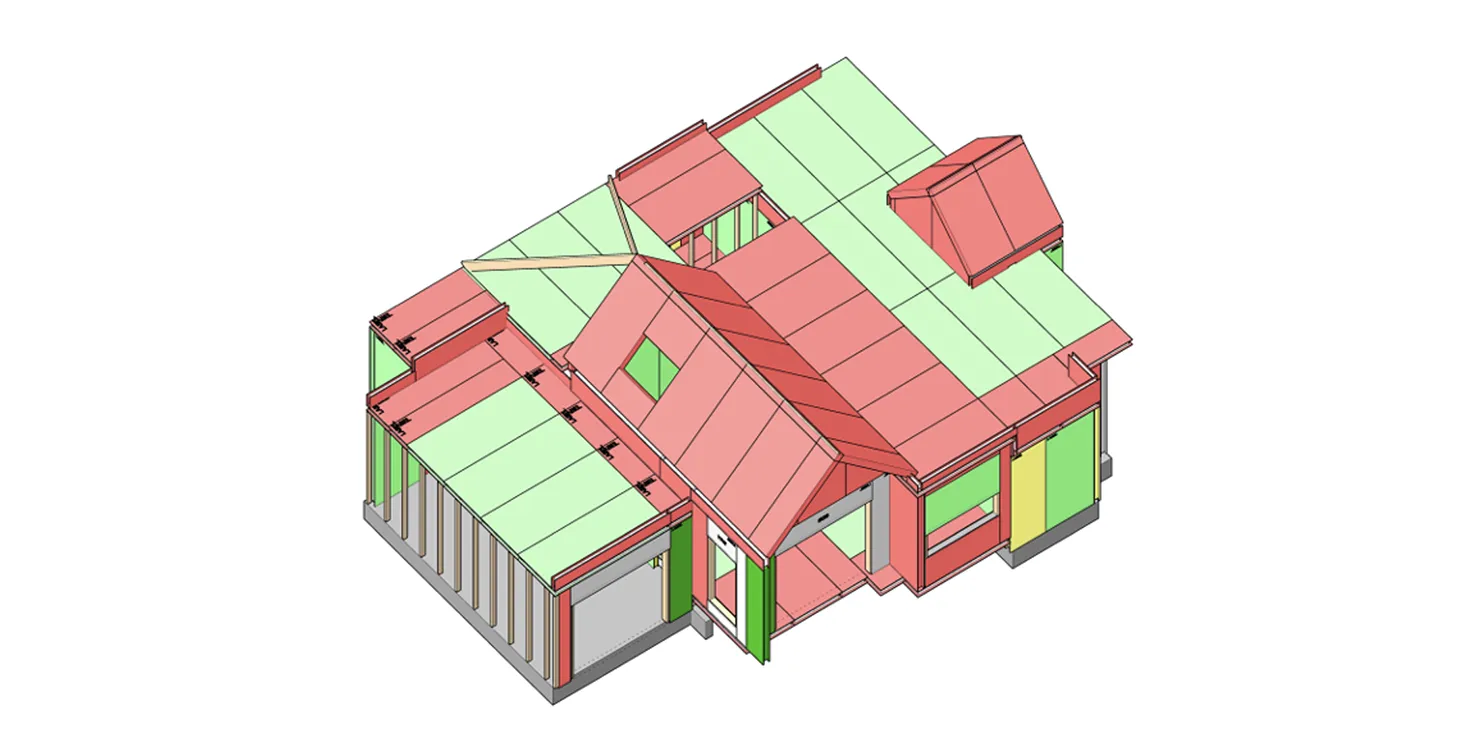

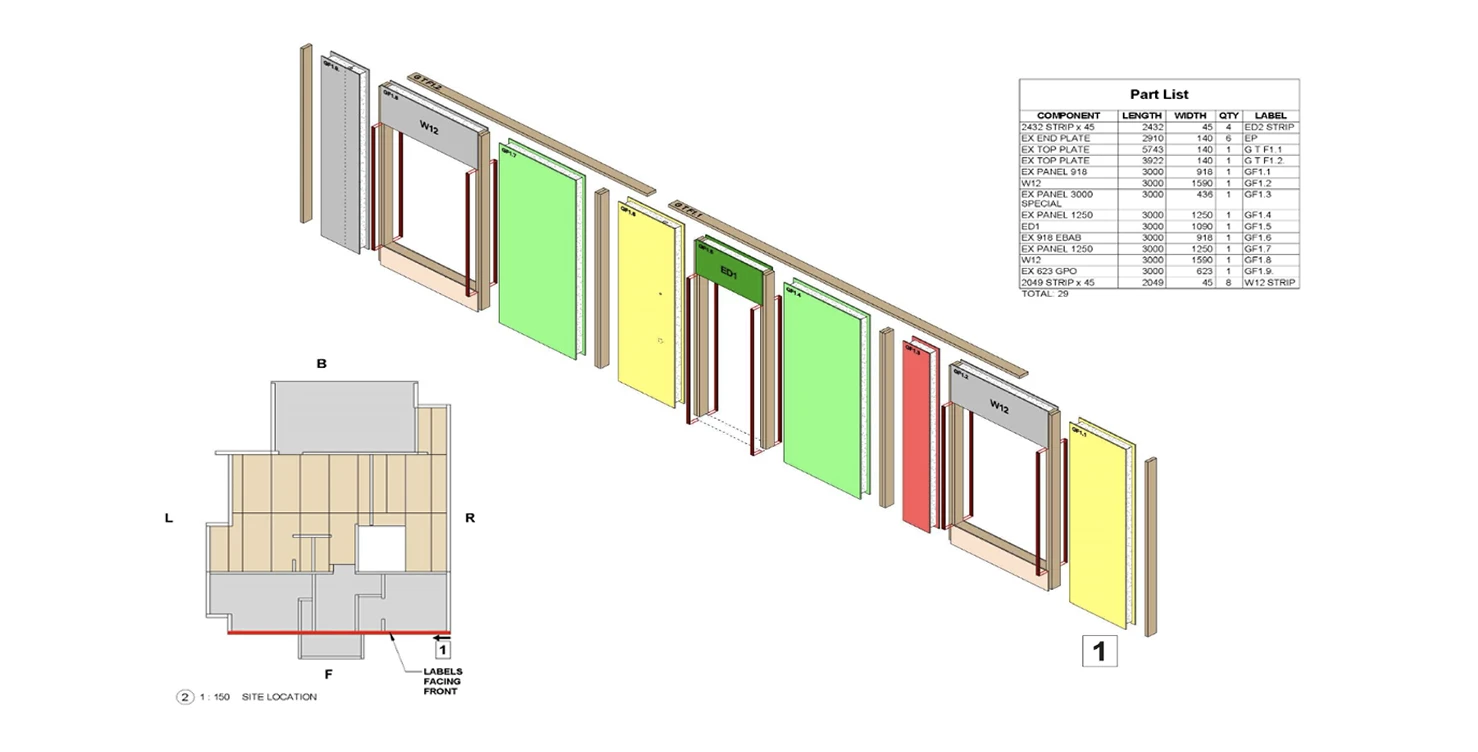

The design process begins with our in-house architects; they will convert your floor plans or alternatively your choice of our suite of house designs into detailed SIPs diagrams. These accurately represent the size and placement of each panel. The diagrams are then used to create a 3D model, providing a visual representation of the complete panel assembly and how the panels will fit together to form the structure. This model allows for precise visualisation of the finished building, ensuring the SIPs panels are designed to optimise both the structural integrity and energy efficiency of the project. Through this process, we ensure that each panel is customised to the specific requirements of the build, with a focus on seamless assembly and performance. From this 3D model the manufacturing and site drawings will be issued and signed off by both client and structural engineer, they are then sent to the factory manufacturing.

STAGE 2: Manufacturing

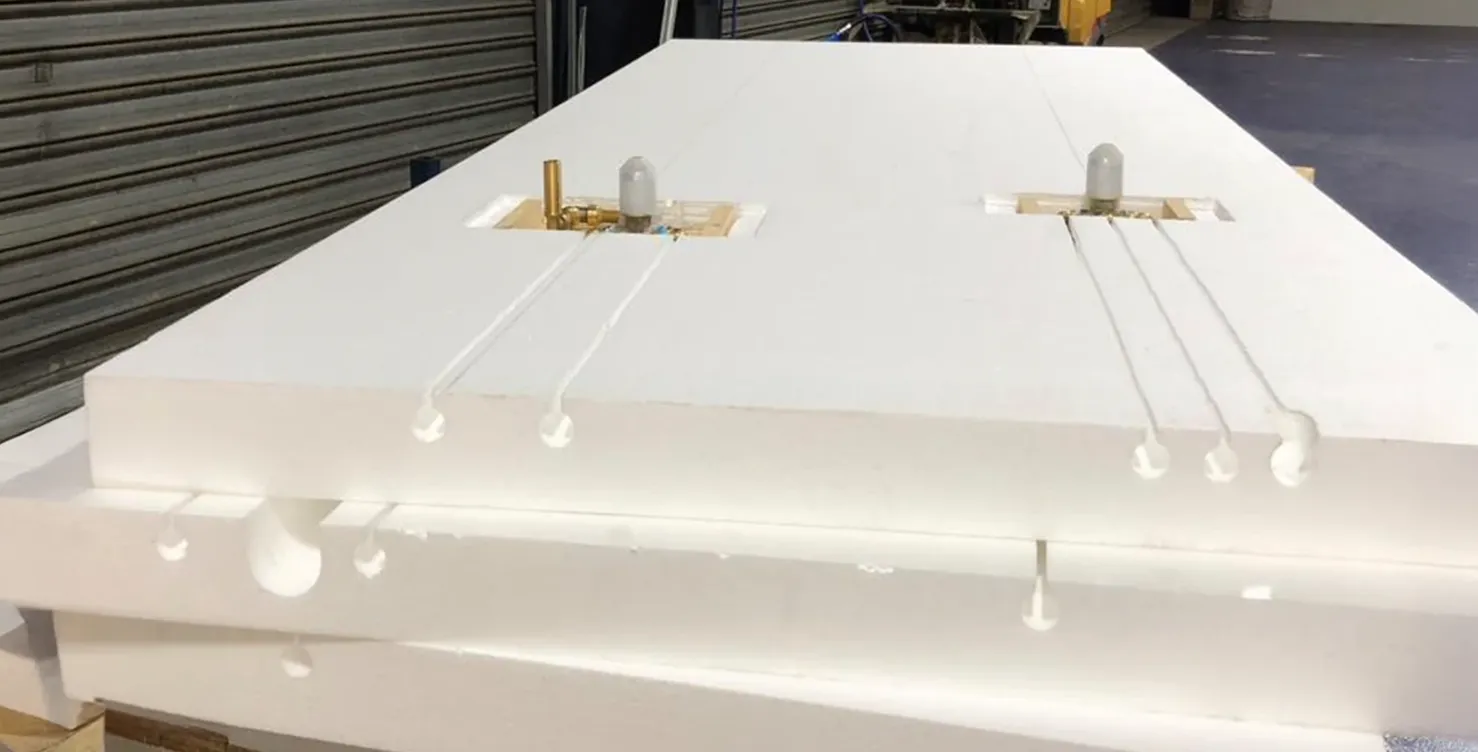

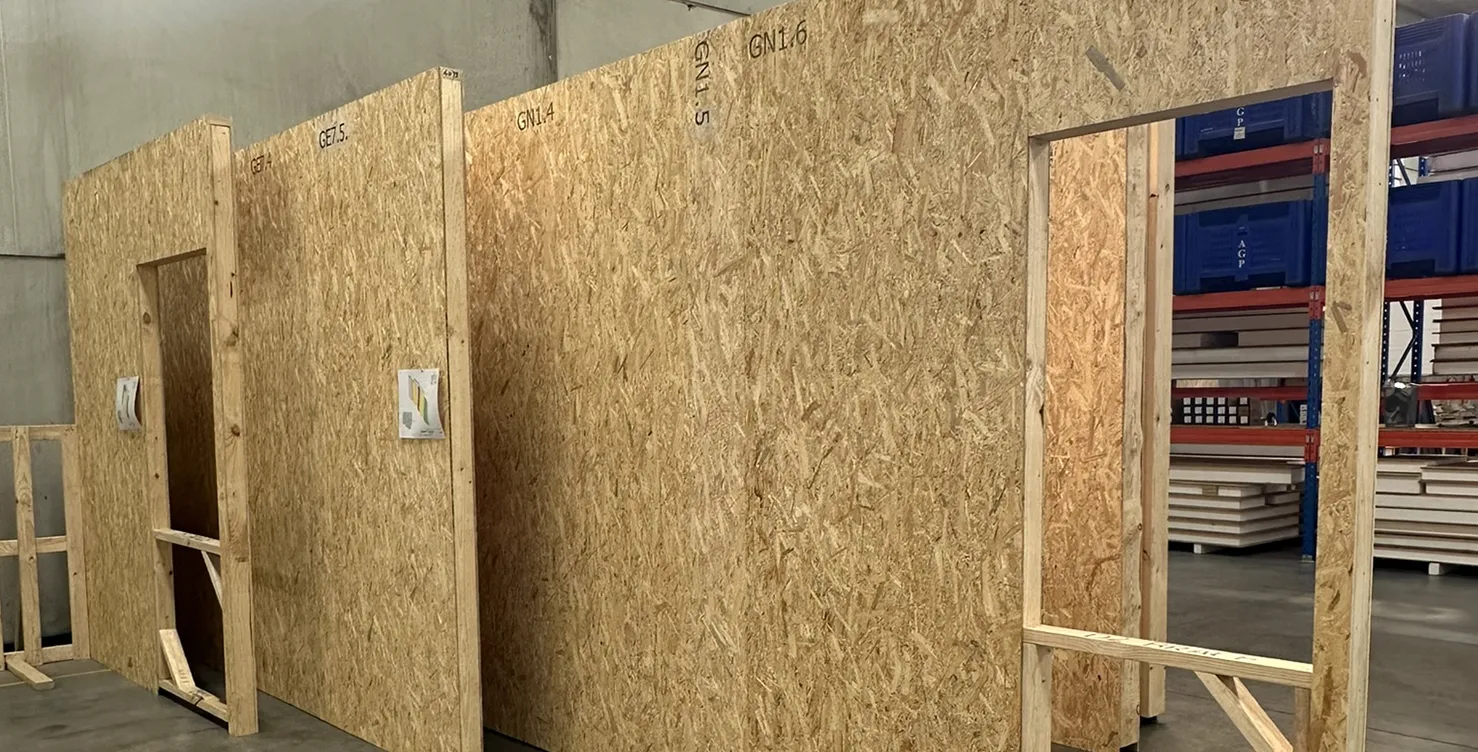

Based on the manufacturing drawings our factory staff select the correct number of OSB (Oriented Strand Board) and EPS (Expanded Polystyrene) to be run through our state-of-the-art panel machine which uses hot glue to laminate the OSB to the EPS core and create the SIP‘s (Structural Insulated Panels). At this point in time any service panels for electrical and plumbing are cored and run through the machine. The completed SIPs are then cut to size based on the architectural drawings this includes all window, door, service, roof and floor panels required for the job. Whilst this is occurring the MGP or LVL timbers are cut to size for the bottom and top plates plus the required number of splines. All items are labelled and refer back to the drawings for installation purposes. At this stage depending on the customers requirements the panels and timbers are packed ready for transport, or they are assembled into wall sections to make for quicker site installation.

STAGE 3: Packing & Transport

The SIPS are packed in the sequential order that they will be installed onsite to ensure ease and speed of installation. If they are packed as panels on pallets they will be loaded via forklift on a flat top semitrailer with a buggy forklift attached for unloading onsite. They can also be packed as full wall and roof sections where they are stored in stillages with the whole stillage being loaded upright on to the crane truck and unloaded wall by wall via crane directly into place onsite. Both options present a more efficient and speedy installation compared to other construction methods. This allows for a single story 130sqm house to be installed in a matter of days, this ensures the builder reaches lockup far quicker than a traditional build.

STAGE 4: Assembly & Completion

To start onsite the bottom plates are fixed to the slab or stumps, this allow for the panels to be placed on top and screwed down. This will generally be done by an onsite crane or crane truck where they can be lowered into place for the install crew to nail down. Once all the internal and external walls are installed the roof can be lowered on top of the load bearing walls. At this stage the windows, doors, and exterior cladding can be installed, and the house reaches the lock-up stage. This marks the point where the building is secured, airtight and weatherproof, allowing interior trades to begin their work. Now electricians, plumbers, and other tradespeople can complete their fit-off and interior tasks, such as installing wiring, plumbing fixtures, and the finishing touches. With the structural framework provided by the SIPs panels in place, the house is now ready for the final steps of construction, leading to a completed, fully functional home.

Why wait weeks? Build in days.

Contact us

If you're interested in working with us or need more info, please fill out the form on the right. Alternatively, feel free to reach out to our team via email or phone.

Enquiries

contact@paneltechsystems.com.au

Call 0404 045 277

Address

U5, 28-50 Cyanamid St

Laverton North, VIC 3026